We offer:

- labels for all industries

- custom shapes

- different adhesives

- hot foil stamping

- several varieties in one run

- 48-h express production

- free delivery in EU and UK

- personalisation

Bespoke Labels in Different Shapes and Sizes

Our online calculator allows you to compare prizes for different shapes, sizes, quantities and variations of labels for your products, in real time. So, whatever industry you come from and whatever product you sell, with our calculator you can find out which parameters work best for your labels.

Why Product Labels Matter

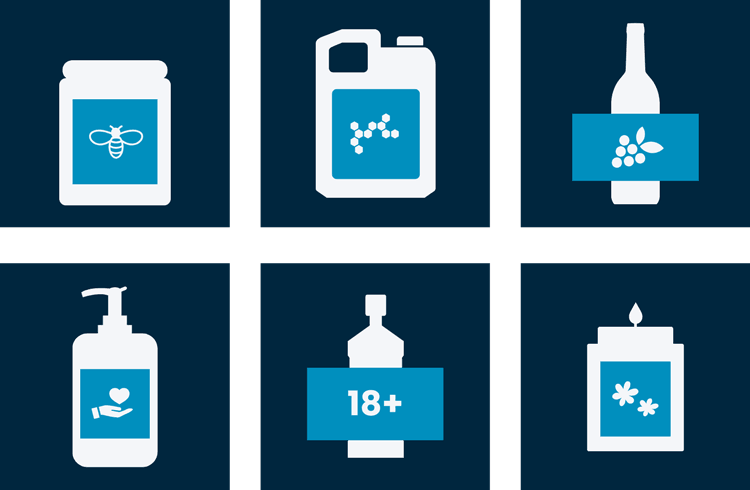

Every day, we use dozens of different products from a wide variety of industries. Whether food, beverage, cosmetics or pharmaceuticals – there is one thing these products have in common: they need labels for various purposes. Be it for product identification, content information, barcode placement, decoration or simply to be able to distinguish the products from one another. It’s all about labels.

Labels Matter because:

#1 You can convey all important and mandatory information on them.

#2 They are a great means of communication with your customers

#3 Depending on the product, they can be a creative outlet for you and your brand

However, these points only scratch the surface of possibilities to embrace with your labels and their design. Check out our online label gallery, to get an idea of what a great label can do for your products:

Practical and Decorative

We don’t just print product labels, we also design them. Our design service is a unique opportunity for you to create a stunning look for your label. The talented designers at label.co.uk are happy to help you implement your ideas!

Amazon Transparency Labels

Convince Yourself of Our Products