High-quality labels and your possibilities with label.co.uk

Labels with High-Quality Finishing

Put your products in the limelight and make your labels real eye-catchers with one of our finishing touches! You can use them to specifically highlight individual lettering or your logo. On top of that, we offer film lamination as an additional protection against abrasion and moisture for your labels. Plus, we provide you with embossed labels:

- as labels on rolls or

- sheet labels (on request)

- with different adhesive strengths

Our Finishing Options

Find out on this page which finishing options are available to you at label.co.uk. Do you have specific questions about a particular finish or would you like to request samples?

Labels with hot foil stamping have a particularly high quality. The foil is applied to the paper using a tool and heat. An image contour, writing or specific area can be refined in this way, making your labels an eye-catcher! The resulting labels are referred to as embossed labels or labels with hot foil.

Many printing companies don’t offer labels with hot foil stamping – but for us, they are an absolute standard.

Blind embossing creates a deformation of selected parts of the label without the use of foil. This technique is great for visibly and tangibly emphasising letters or more abstract shapes.

label.co.uk specialises in high-quality labels with positive embossing (raised elements). Blind embossing is a classic finishing technique in label printing. The elevated parts of the surface create an interesting play of light and shadow.

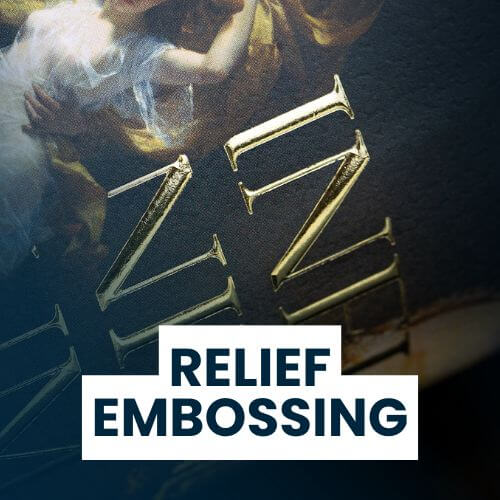

Relief embossing or relief cut embossing is a combination of blind embossing and hot foil stamping. The use of foil gives the professionally printed label a particularly high-quality look!

Relief embossing is considered the queen of refinements. The various levels hereby created are emphasised in several further processing steps. This creates an exciting 3D effect as well as a premium look and feel.

We will explain step by step how to correctly apply hot foil on labels. In the tutorial, the hot foil is applied in gold. Of course, the it can also be embossed in other colours:

- metallic or transparent

- matt or glossy

- gold, silver and hologram foil

- copper, bronze and rose gold look

- pink, red, orange, blue or green

- and many more on request!

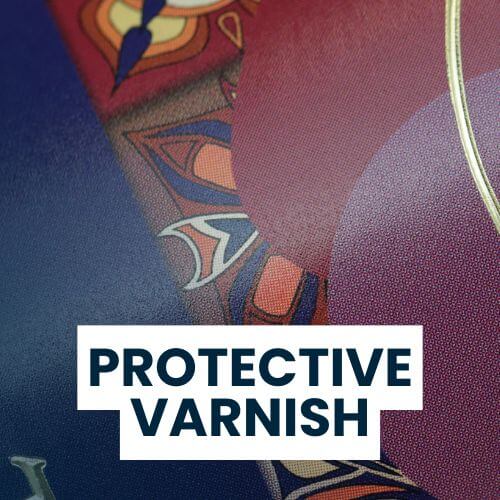

Protection against abrasion with protective varnish! It can be applied to the labels after the printing process.

The transparent varnish covers the label like a protective layer. This makes the labels more robust. In addition, the labels look more shiny. We offer protective varnish in matt or gloss.

Do your labels require special protection or a striking gloss? This is where film lamination comes into play. The labels are covered with an extremely thin, durable film.

Compared to a normal protective varnish, the glossy or matt protective lamination is slightly thicker and more durable.

An extra touch of glamour! The transparent varnish is digitally applied to certain areas of the high-quality label to refine and emphasise them.

Digital spot varnish is applied without the use of tools, instead using a special machine. This not only saves costs, but also time and resources!

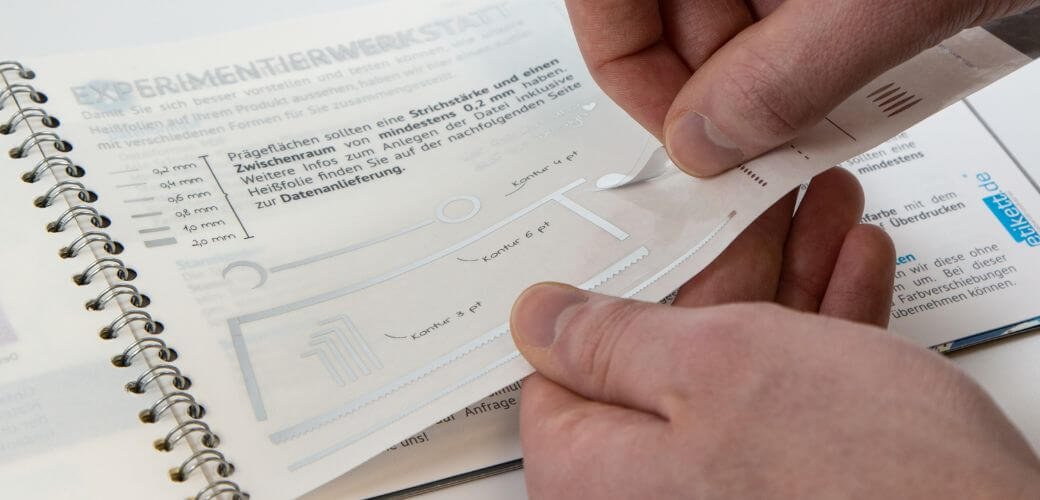

Request a sample book or samples

Try before you buy! If you want to test the materials live, we recommend our free sample book. Alternatively, we will put together a customised sample folder for you on request. Feel free to call us on +49 (0)6502 – 984 940 or write an email to info@label.co.uk.

Perfectly finished labels

First of all, you can choose from a variety of paper and film types to find the perfect fit. Our materials are as versatile as the printing on them. One thing is certain: we produce your finished labels to the highest quality, taking your products‘ look to the next level!

We will help you find the ideal label with high-quality finishing.