Labels with hot foil stamping and your advantages with label.co.uk

- exclusive look & quality

- high colour intensity

- effective eye-catchers

- additional gloss

- filigree details

- free choice of colour / format

- free delivery in the EU & UK

Hot Foil Stamping Is Used in Versatile Ways

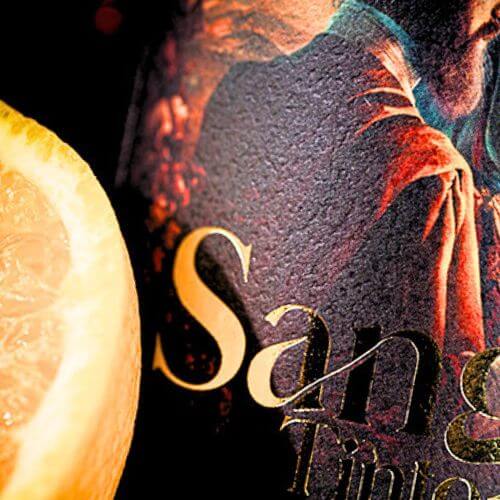

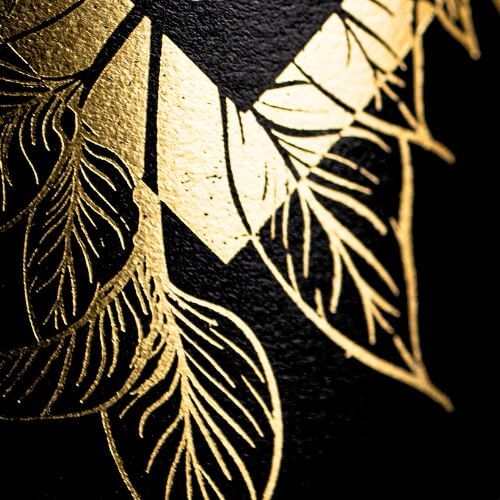

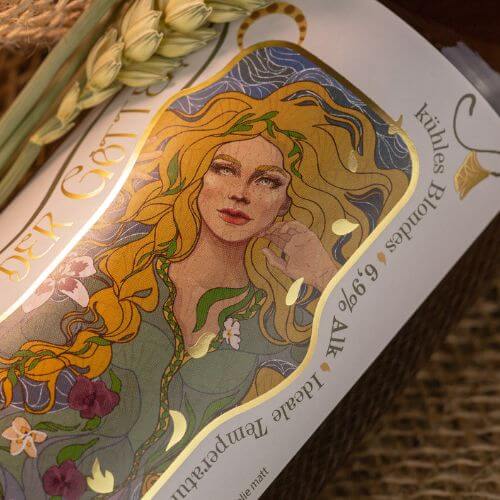

Roll labels with hot foil stamping are particularly popular for standing out from the competition and drawing the customer’s attention to your own product.

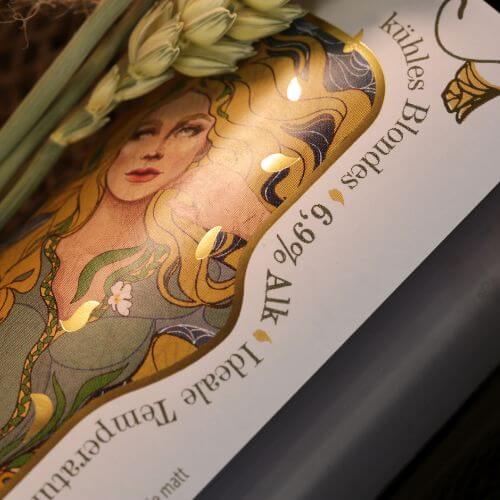

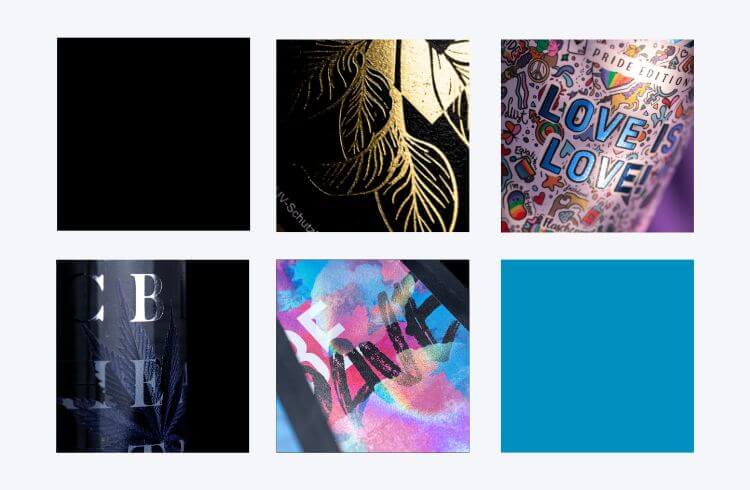

Embossed labels are often found in the wine, champagne, spirits or cosmetics industry and on high-quality food products. Hot foil stamping gives your labels a special surface texture that refracts light. It can also be combined with numerous other finishes and you can have your labels embossed with multiple hot foils in different colours.

You should ensure that your products leave a personalised, exclusive and unmistakable impression. Labels of this type are often called embossed labels, but hot foil labels as well as labels with foil embossing are also common names. If you opt for customised labels with high-quality hot foil stamping, there are various aspects to consider:

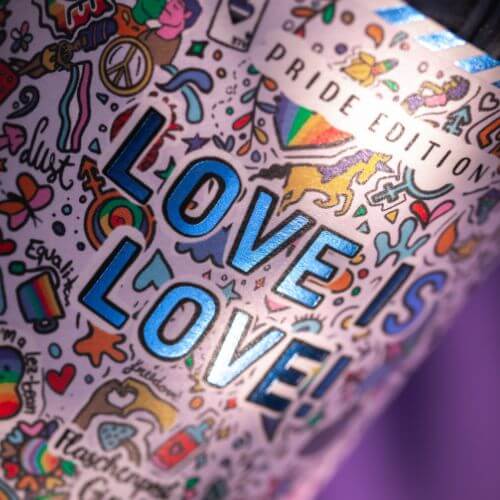

Thanks to hot foil stamping, sophisticated details that create both visual and tactile contrasts can be realised in a particularly elegant and delicate way. In the online calculator, you first select parameters such as quantity or material. Then decide on the right hot foil.

What Happens During Embossing?

If labels are embossed with hot foil, a wafer-thin film is applied to the surface of the label in the desired places. These coloured or metallic foils are embossed onto the material of your label using special embossing tools and heat.

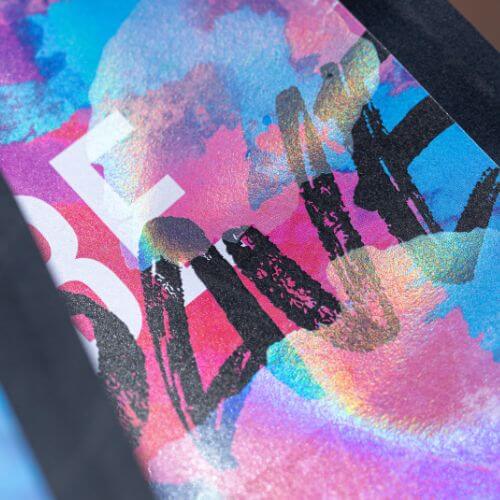

Almost all of our label materials, whether untreated, film-laminated or coated, are compatible with hot foil stamping. We offer a wide range of diverse, combinable hot foils so that there are no limits to your creativity. These include the following foils:

- metallic or transparent

- matt or glossy

- gold, silver & hologram foil

- copper, bronze & rose gold look

- pink, red, orange, blue or green

- and many more on request!

…

Hot Foil Stamping: Correct Print Data with label.co.uk

Regarding correct print data, there are various aspects to consider for labels with hot foil stamping. Of course, we offer artwork services and are happy to help you with this! Have your print data checked and corrected by selecting the appropriate package.

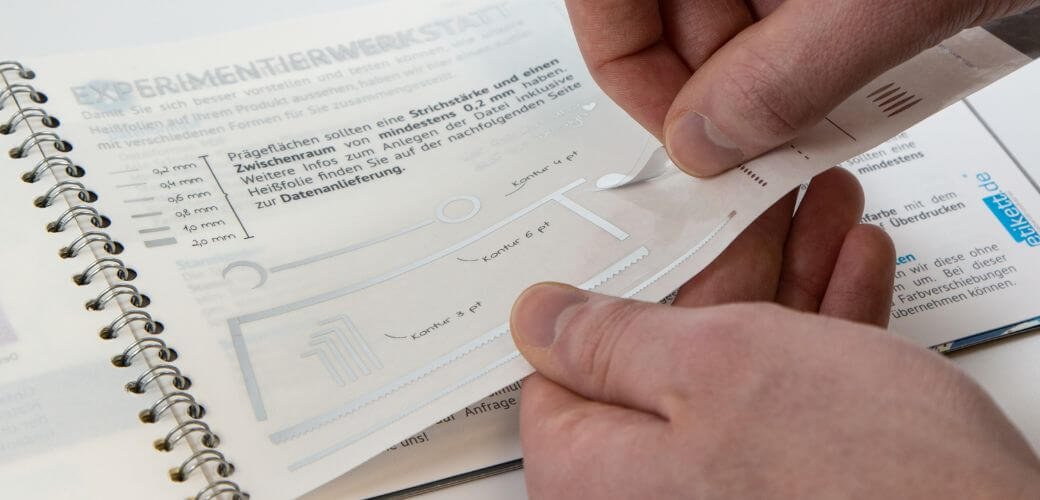

Alternatively, you are welcome to download our free handout on the delivery of printable data. Please note that elements and fonts to be embossed must have a minimum line thickness of 0.2 mm, blank spaces and negatively recessed elements at least 0.4 mm. If you have any further questions about the technical aspects of creating correct print files, take a look at our tutorials.

Print Data Professional in Minutes

Would you like to create the print data for your labels with hot foil stamping yourself?

Our tutorials will help you! We have put together a collection of videos, texts and images that explain in detail how to create print data for labels with hot foil stamping.

We will explain step by step how to correctly apply hot foil for a label. Please note the following:

- Set colour as spot colour

- Set spot colour to overprint

- Check colours using the separation preview

In the tutorial, the hot foil is applied as an example in gold. Of course, the hot foil can also be embossed in other colours. The important thing is that you set up the hot foil as a spot colour with the name Foil and set it to overprint.

Note: Unwanted deviations sometimes occur when applying the

hot foil.

If elements such as borders – around letters e.g. – are embossed, the position of the foil may change slightly during production. In addition, very thin elements can spread on structured material.

Production, Pressure and Material

Hot foil stamping uses a special tool, heat and pressure. The same tool is used several times and presses the foil onto the label material in the chosen position. At label.co.uk we use magnesium tools as standard, but you can of course choose on request:

- Magnesium tool

- Brass tool

On one hand, production-related fluctuations can occur when using the tools. This means that in some cases embossed elements are not placed 100% in the desired position. Furthermore, the pressure level changes the look of the embossed elements. To emboss larger areas more pressure is required than with smaller elements. For this reason, the results may differ if an embossing tool contains small and large elements. We therefore recommend having several tools made in these cases. This allows each element to be embossed with optimum pressure according to its size.

On the other hand, there are material-dependent characteristics: For example, large-area hot foil stamping with filigree cut-outs on certain materials can result in deviations, such as spreading. In addition, coloured foils are often thinner than other foils and are therefore not suitable for textured materials such as cotton paper. Of course, we will be happy to advise you on this! We also recommend our proofing service. This will ensure that your label looks as planned.

Magnesium vs. Brass

A tool made of magnesium is cost-effective in the short term and makes for sharp edges. In comparison, the brass tool is a more cost-intensive alternative and is recommended for filigree elements that are to be embossed. In addition, a brass tool is more durable, can be reused more often and therefore saves costs and resources in the long term.

Want to Try It?

We produce a small quantity of your labels with hot foil stamping under original printing conditions. Take advantage of our proofing service.

This allows you to test whether you are satisfied with the print result and make sure that everything later corresponds to your original ideas!

many different colours

& effects

texts, elements or

filigree details

several foils on

one label

Choose the Right Material

At label.co.uk, we offer a large selection of materials that can be combined with hot foil stamping for printing your customised labels. Depending on whether you prefer paper labels or vinyl labels, there are various options to choose from. We also offer various sustainable solutions. You do not have to compromise on aesthetics or functionality.

If you would like to have the labels produced on a very specific material, you can contact us. label.co.uk offers the right solution for every application and situation! On request, we can activate materials for you in the online calculator.

... and the Right Adhesives

Depending on where your labels with hot foil stamping are used, you will of course also need different adhesive properties. Among other things, we offer:

Free Sample Book …

Request your free sample book today. It contains countless design ideas and various tips. It also contains pre-cut labels.

You can put them to the test and apply them to your products. This allows you to convince yourself not only of the look and feel of our materials, but also of the print quality and adhesive strength.

Test first, then order! If you want to test the films, papers and materials live beforehand, we recommend our free sample book. Alternatively, we can put together a customised selection of samples for you on request.

Please feel free to contact us by phone at 0203 588 1080 or by e-mail at info@label.co.uk.

Hot Foil with 3D Effect?!

When hot foil stamping is combined with blind embossing, the result is relief embossing. It is considered the queen of finishings. Thanks to the interplay of blind embossing and hot foil stamping, the refined elements are shown to their best advantage and an exciting 3D effect is created that you can not only see, but also feel.

The material is moulded at the desired point using an embossing tool and then additionally finished with a hot foil. Blind embossing, on the other hand, dispenses with colour highlighting and only impresses with its partial deformation. label.co.uk specialises in positive embossing (raised elements). The tactile contour enhances the labels not only haptically but also visually. The difference in texture also makes for an interesting interplay of light and shadow, creating an absolute visual highlight.

Only our hot foil stamping is shown in the online calculator. If you would like to have your labels embossed in relief or blind embossing, please contact us and we will be happy to help you.

Experiment with Hot Foils

To help you visualise and test how our hot foils will look on your product, we have put together a selection of various shapes and silver hot foil for you in our free sample book.

Metallic Labels as an Alternative

Hot foil stamping is not the only way to create a special metallic effect. In addition to paper or vinyl labels with hot foil stamping, we naturally also offer metallic labels. This is a cost-effective alternative to hot foil.

An Extra Dose of Protection for Your Labels

Finishes score points above all because of their aesthetic aspect. In addition, finishes can also be functional! We offer protective varnish in matt or gloss and film lamination.

Protective varnish not only gives your label a higher-quality or more eye-catching surface, but also protects it from normal abrasion. The properties of the protective varnish should be matched to the material of your label and the hot foil: For example, using glossy hot foil, we recommend choosing glossy protective varnish. In case of film lamination, on the other hand, a transparent film is applied to the label as an additive that protects against more severe abrasion. Both finishes can be combined with hot foil and provide your label with an extra dose of protection against external influences.

Dispatch & Further Processing

Printing customised labels with hot foil stamping can be time-consuming. But it doesn’t have to be! The production time and delivery period are displayed directly in the online calculator at label.co.uk. In certain cases, you can select express production, which means you will receive your labels even faster. Please note that the production time may be delayed due to incorrect print data or the production of an embossing tool, for example. We also offer various dispatch options.

After production and delivery of your labels with high-quality hot foil stamping, automatic, semi-automatic or manual labelling takes place. We have summarised common labelling techniques for you to help you prepare for this final step!

What Happens Next?

You can find more information about our various finishes on our overview page. In addition to hot foil stamping, there are other options such as blind embossing, relief embossing and digital spot varnish. In the online calculator, you can configure your customised labels with hot foil stamping in just a few steps! If you can’t find what you need in the calculator, please contact us. We will support you. Please feel free to contact us by phone at 0203 588 1080 or by e-mail at info@label.co.uk.

No Design Yet?

No problem! Our free sample book will help you find ideas and provide you with plenty of inspiration. Our design expert Mirsad will also give you some tips on designing labels.

If you still need help after that, our creative minds are at your side! Our design service will create your customised label. A graphic designer will work with you to create the perfect look for your label with hot foil stamping.

Questions? We’re

here to help!