Labels with relief embossing and the advantages of label.co.uk

- exclusive finish

- effective eye-catcher

- special 3D effect

- high-quality look

- unique feel

- tangible quality

- free in shape and design

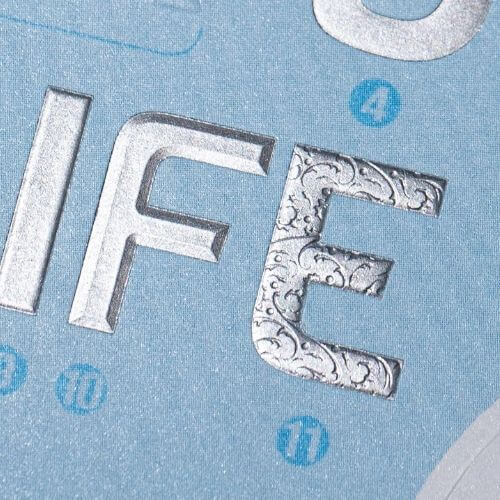

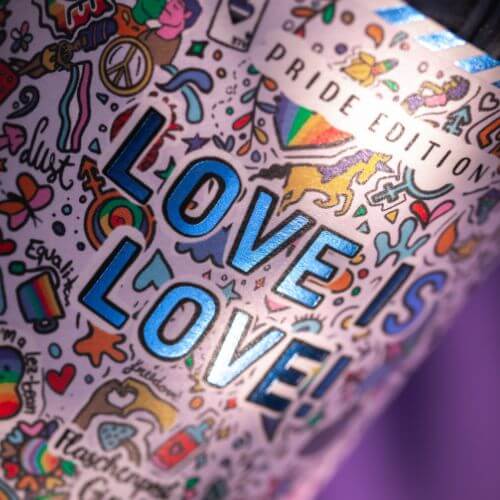

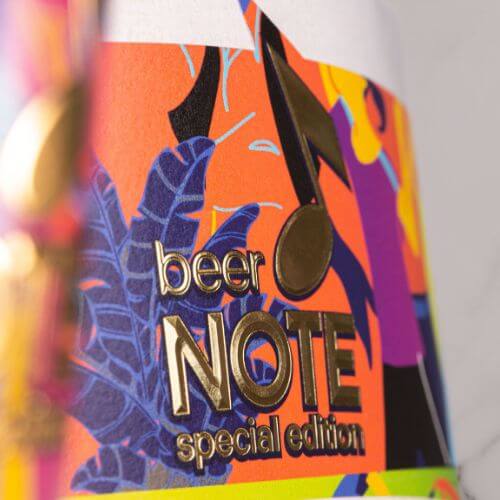

That Certain Something: Labels with Relief Embossing

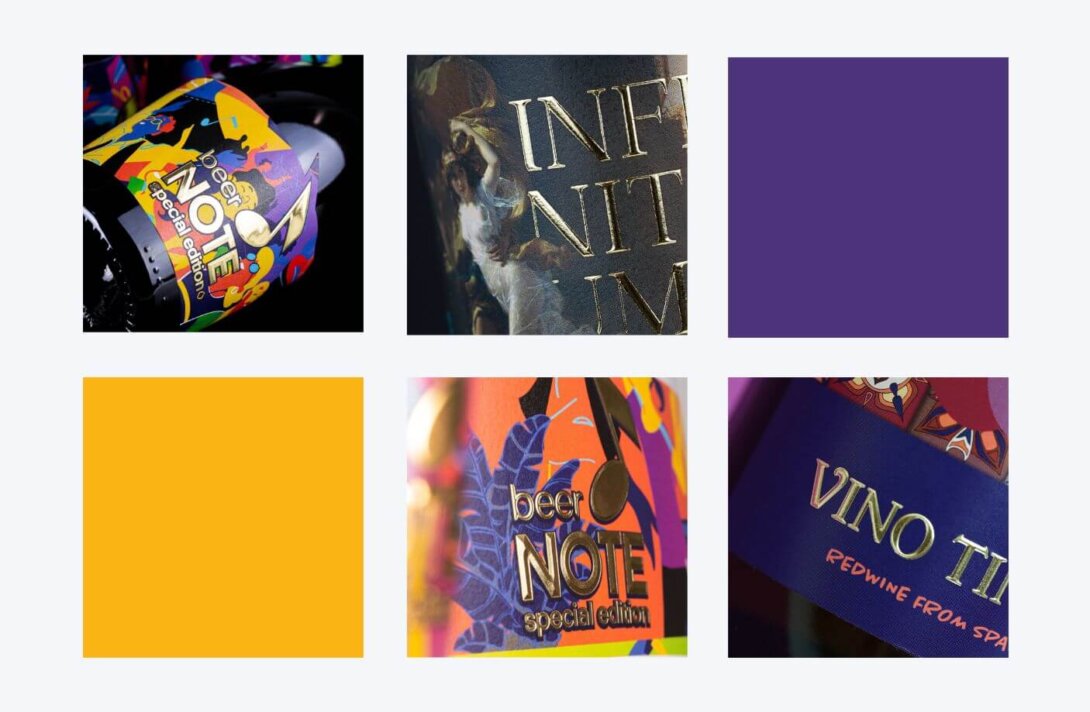

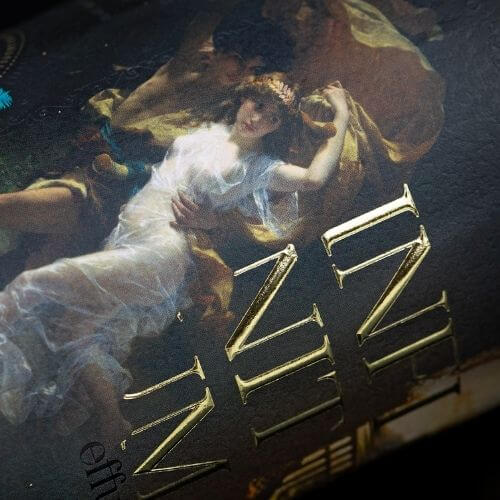

Compared to conventional labels without finishing, labels with relief embossing stand out from the crowd! This finish is a visual highlight, and is considered the ‘queen of finishes’ for a reason. Relief embossing is often used for wine labels, cosmetic labels, spirits labels or for labels on other luxury products.

Relief embossing impresses with a partial deformation of the label material, which is additionally finished with a foil. It is therefore a combination of blind embossing and hot foil stamping. This creates a 3D effect with a unique charm, that gives the individual label that certain something! Basically, any element can be embossed using relief embossing, including fonts, logos, structures or abstract shapes. There are no limits to creativity here.

You cannot choose relief embossing –which creates a visual and tactile effect – in the online calculator. If you are interested in this option, please contact us by phone on 0203 588 1080 or by email at info@label.co.uk.

How Does Relief Embossing Work?

When labels are given relief embossing, a mould is created on the surface of the label at the desired locations. These locations are then additionally finished with hot foil. This is done using a tool as well as heat and pressure.

At label.co.uk, your embossed labels are created by elevating certain areas and giving them a tangible contour. We distinguish between embossing (raised elements) and debossing (recessed elements). We don’t offer debossing for our labels.

The intensity of the embossing depends on the type of embossing tool and the density of the material. It should be noted that relief embossing can only be used on paper and not on film.

…

Labels with Relief Embossing: Correct Printing Data

When it comes to labels with hot foil stamping, there are various aspects to consider with regard to the correct printing data. Of course, our artwork service team will be happy to take care of this for you! By selecting the package that is tailored to your needs, the printing files for your label with relief embossing will either be created or adapted.

When planning out your labels, please consider that elements and fonts on your roll labels that are to be embossed must have a minimum line width of 0.4 mm, and blank spaces between embossed elements must have a minimum line width of 0.6 mm.

Become a Printing Data Pro

Do you want to create the printing file for your labels with relief embossing yourself? Please use the following tools as a guide:

Production, Print Run and Material

Relief embossing uses a special brass tool, heat and pressure. The same brass tool is used multiple times to create a deformation and press foil to the label material in the desired place.

Production-related variations: In some cases, embossed elements are not placed 100% in the desired position. Furthermore, the pressure affects the appearance of the embossing on your roll label with relief embossing. Larger elements require more pressure than smaller elements. For this reason, there may be varying results if an embossing tool contains small and large elements. We recommend having several tools made in these cases. This allows each element to be embossed with ideal pressure according to its size.

Material-dependent variations: When using large-area relief embossing with filigree cut-outs, certain materials may be subject to variations, such as running or tearing in the film. Furthermore, coloured foils are often thinner than other foils and are therefore not suitable for structured material such as cotton paper. The size of the embossed area is also limited: larger areas can cause indentations, which reduces the raised effect. Of course, we will be happy to advise you on this!

How about a Test Run?

On request, we can produce a small quantity of your labels with relief embossing under original printing conditions. Please feel free to contact us by phone on 0203 588 1080 or by email at info@label.co.uk.

Use our printing service to check for possible variations or fluctuations. You can also test the material, quality and adhesive strength.

Texts, elements

or filigree details

Embossing tool made

of high-quality brass

Test relief embossing

with a print proof

Materials & Adhesives for Labels with Relief Embossing

Our online calculator allows you to choose from a variety of materials. However, relief embossing can only be applied to paper labels. We have the right papers for your labels with relief embossing, tailored to your requirements. Will your customised embossed label be exposed to moisture or extreme cold? Depending on where your labels will be used, you will need the right adhesive. Among other things, we offer:

If you want to put the materials and adhesive strength for your relief embossed label to the test in advance, we recommend our free sample book.

Try before You Buy!

Request your free sample book today. It contains countless inspiring design ideas and helpful tips. It also includes pre-cut labels that you can stick on your product to try out. This is an easy way to test films, papers or adhesive properties with your own eyes.

Alternatively, we can put together a customised sample folder for you on request. Please feel free to contact us by phone at 0203 588 1080 or by email at info@label.co.uk.

Embossed Labels: Alternatives, Options & Extras

Combining hot foil stamping with blind embossing creates relief embossing. The material is shaped at the desired location using an embossing tool and then finished with hot foil.

Hot foil stamping: If you want to forego the 3D effect or partial deformation for your custom labels but still want to highlight them with foil, we recommend hot foil stamping.

Blind embossing: If you are interested in a stylish, minimalist design, blind embossing is the perfect choice, as it impresses with only a partial deformation of the material, without foil!

Finishings always create an interesting play of light and shadow, making your labels a real eye-catcher. Of course, you can combine various finishing options on your label. However, only our hot foil embossing is shown in the online calculator. If you would like to add relief embossing or blind embossing to your labels, please contact us and we will be happy to help.

Metallic Labels

For roll labels with relief embossing and hot foil stamping, hot foil is used, which shimmers either in matt or glossy and, depending on your choice, in colour or transparent. Hot foil is not the only way to create a special metallic effect, though.

In addition to paper labels with relief embossing or labels with hot foil stamping, we also offer metallic labels. These are a cost-effective alternative to hot foil. Please note that partial embossing is not possible with metallic labels.

Special Protection for Your Labels with Relief Embossing

Film lamination and protective varnish are among the finishes with protective properties. While film lamination involves a special transparent film that is applied to the label, the protective varnish is an initially liquid substance that covers the material surface and dries. Due to the characteristic deformation caused by relief embossing, the additional application of a protective film is not possible.

So, relief embossing cannot be combined with film lamination, but only with protective varnish. Protective varnish gives your label a higher-quality surface and protects against abrasion. The properties of the protective varnish should be matched to the material of your label. For example, we recommend a glossy protective varnish for glossy hot foil.

The Right Design

You don’t have a design for your embossed label yet? We will help you on your way to the perfect label! First, let yourself be inspired by our free sample book. In addition, our design expert Mirsad provides some tips for designing labels.

Furthermore, our design service team is at your side, working with you to develop the perfect look for your label with relief embossing.

Shipping and Further Processing

Having custom labels with relief embossing printed can be time-consuming. But it doesn’t have to be! In addition to our quick production and delivery times, you can in some cases select express production, which means you get your embossed labels even faster. Please note that the production time can be delayed, for example, by errors in your printing data or the production of an embossing tool. We also offer a range of shipping options.

Once your labels with high-quality relief embossing have been produced and delivered, labelling can be done either automatically, semi-automatically or by hand. We have summarised 5 labelling techniques for you to help you prepare for this final step! Please note that for roll labels with relief embossing, you must specify the correct winding direction in advance to ensure successful labelling.

What Happens Next?

You can find more information about our various finishes on our overview page. Besides relief embossing, there are other finishing options such as hot foil stamping or blind embossing and digital spot varnish. If you can’t find what you need for your roll labels with finishing in the calculator, please contact us. We will be happy to help. You can reach us by phone at 0203 588 1080 or by email at info@label.co.uk.