23 September 2023

How to Label Your Products

Once a label has been designed and produced, it’s time to put it on your products. From time to time we get questions about the application of labels and the advantages and disadvantages of certain processes. Although we do not offer services for applying labels to products, we at label.co.uk are happy to provide an overview of the most commonly used processes:

- Automatic labelling

- Semi-automatic labelling

- Manual labelling

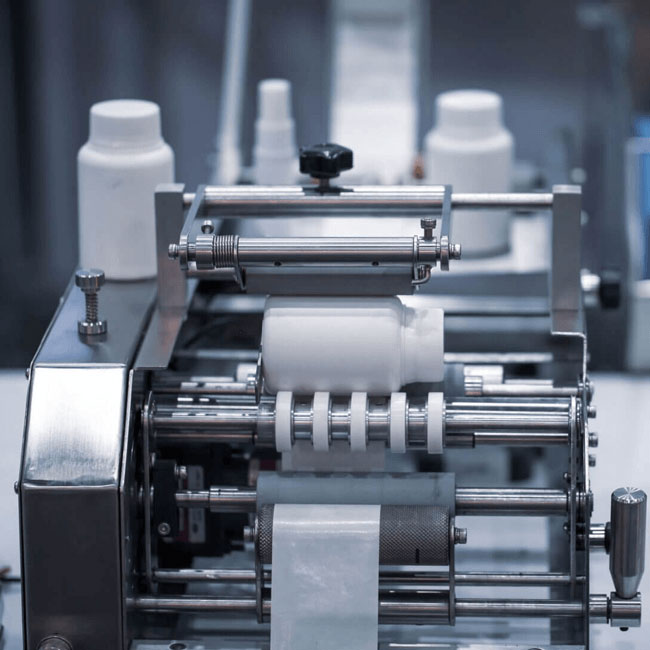

Automatic Labelling

Efficient and precise: The method provides high efficiency for large production volumes and minimises potential sources of error.

Speed & productivity: Fully automatic labelling machines can apply an impressive number of labels in very short amounts of time which increases productivity and significantly reduces processing times.

Precision: Thanks to modern technology, fully automatic processes ensure precise positioning of the labels. This minimises the risk of labels being displaced or applied crookedly.

Consistency & quality: The uniform application of labels to each product makes for a professional appearance. The legibility of the label is guaranteed as there are no creases or other forms of damage.

Error reduction: The use of sensors and automatic control mechanisms makes sure that potential sources of error are detected and avoided. Therefore, the risk of additional costs due to incorrect labelling is reduced.

Semi-Automatic Labelling

Flexibility and control: The semi-automatic method lies between fully automatic and manual labelling, and combines the advantages of automation with the possibility of manual control.

Flexibility: The semi-automatic method allows for different label formats and sizes to be processed. Thus, it is particularly useful when products have varying labelling requirements.

Simple operation: Operation is generally intuitive and does not require extensive training. Employees can quickly learn how to apply product labels.

Manual control: In contrast to fully automatic labelling, employees can monitor the labelling process and make manual adjustments if necessary. This contributes to error-free labelling.

Cost-effectiveness: Semi-automatic labelling machines offer a cost-effective option for companies that want to achieve a certain level of automation without investing in expensive fully automatic systems. Semi-automatic labelling is a versatile method that combines flexibility and control.

Manual Labelling

Precision and individuality: The manual application of product labels is mainly used for labelling small quantities of products. Although automatic methods are widely used, manual labelling is particularly suitable in some cases.

Precision: For complex products or specific labelling requirements, manual labelling ensures greater accuracy. This type of application allows for a more precise placement of the label.

Individuality & creativity: For handmade or artisan products, the method can be an important element in expressing individuality or creativity, where the label can become the hallmark of the product.

Quality control: With manual labelling, employees can visually check each label and make sure that it meets quality standards. This reduces the risk of errors and consequently additional costs.

Flexibility: The process is well suited to small production volumes or special occasions where a high level of customisation and flexibility is required. It allows applications tailored to specific needs. The labels are applied independently of machines or other technology. The person applying the labels simply needs to be familiar with the requirements for the correct application.

Step-by-Step: Error-free manual application:

1. Make sure the surface is clean and dry

2. Place the label (using visual marks for accuracy, if necessary).

3. Press the centre area onto the surface first and press the label firmly outwards so that there are no air bubbles or creases.

4. Make sure that the label is in the correct position, smoothly applied, and adheres well to your product’s surface. Although manual labelling can be more time-consuming than automated methods, it is essential in certain situations.

Katharina Crusius

Marketing