Roll labels are mostly processed mechanically, i.e. they are applied to the product by a machine. When producing roll labels, it is therefore very important to know the requirements of the machine that will process the rolls. The following elements must be taken into consideration:

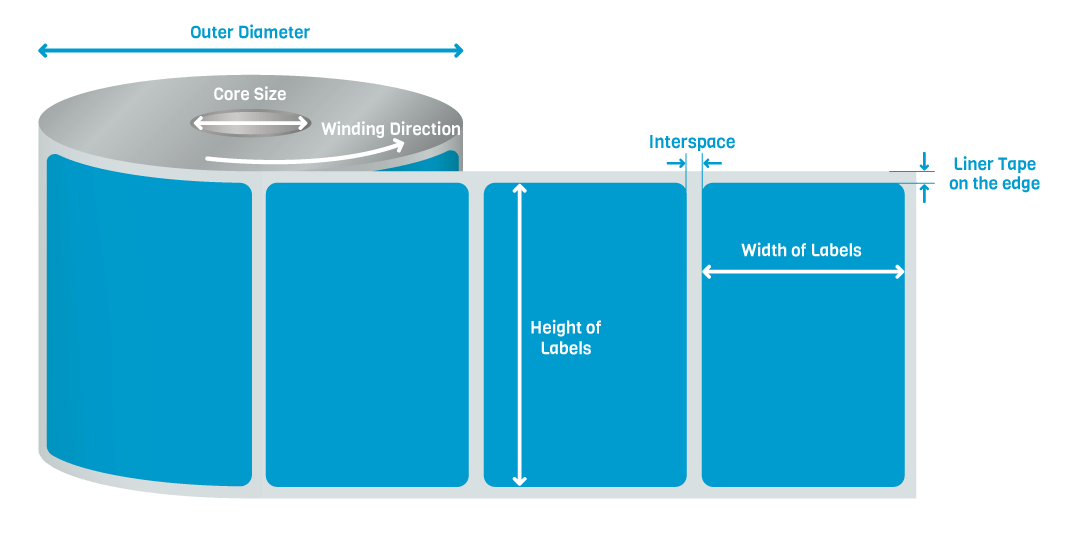

The maximum outer diameter that you can order via the calculator is 350 mm. You can also select the roll size or the number of labels per roll.

You can also select either the size of the roll or the number of labels per roll. The maximum roll size is important so that it will fit easily into your labeller during application. If nothing is specified, the rolls are assembled according to ecologic and economic aspects.

The standard core size we offer is 76 mm (inner diameter). On request and with a surcharge, we also offer core sizes of 40mm and 25mm .

The correct core size is extremely important, especially for machine processing. The specifications depend on the requirements of your machines. For manual application, this information is irrelevant.

If you want to mechanically process your adhesive labels on rolls, it is important to know which winding direction you need for your machines.

There are basically two winding directions for your adhesive roll labels:

- Inner winding

- Outer winding

The printed side can therefore face inwards or outwards.

It is also important to distinguish the position of the labels on the roll. There are four variants:

- Top edge leading

- Bottom edge leading

- Left edge leading

- Right edge leading

It is important to specify here the final format of the label, i.e. without the bleed. The width and height are defined according to the layout and output of the label on the reel.Important: If you need labels in the 50mm x 100mm size, these are the parameters to be entered in our calculator. In your print file, on the other hand, you have to create the work table with the final format plus the 2.5mm bleed on each side.

What does this mean? This is to inform you that the height of the finished roll is the sum of the format ( depends on the winding direction) of your label plus 5mm (2.5mm bleed on each side).

The interspace is the distance between two labels on the roll. This interspace or gap varies from customer to customer, depending on how the labels are further processed and applied to the product.

As a standard we produce with 5 mm interspace between the labels on the roll. A smaller gap is possible on request. However, we recommend 3 mm as minimum interspace. Anything less would make machine processing and weeding more difficult.

The surplus of carrier material is the distance to the edge of the roll. This only applies to the production of adhesive labels on a roll, for the production of sheets this information can be omitted.

The standard is 2.5 mm on both sides, for a total of 5 mm. Larger or smaller gaps are possible on request, but the recommended minimum is 1.5 mm on both sides, for a total of 3 mm. If the minimum value is not respected, difficulties may be encountered in the weeding phase.