Telling Stories with Finishing Touches

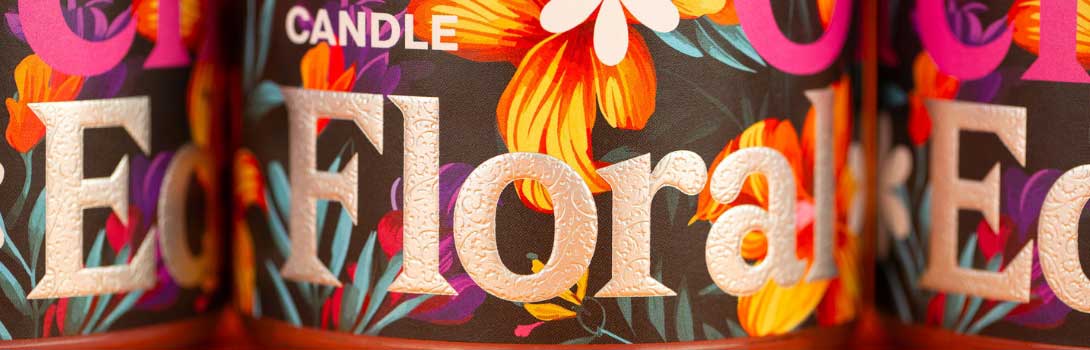

With the right finishing touches, you can create unique, even breathtaking effects on your labels. Used correctly, they add depth to your product packaging and complement the other effects with their special texture and quality. Tactile finishes in particular, such as blind and relief embossing, make your labels tangible. So, in order to exploit the full potential of your labels, you should consider how finishes will contribute to that.

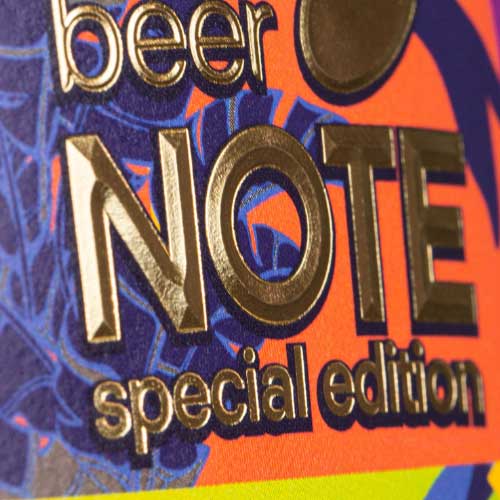

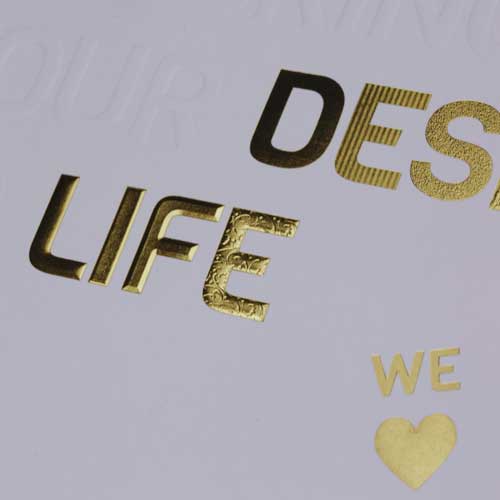

Relief embossing is ideal for a particularly high-quality appearance. It combines the tactile properties of blind embossing with the visual appeal of hot foil stamping. By deforming the material and applying a glossy hot foil, your label becomes a canvas for exciting interplays between light and shadow.

Micro Embossing

For a while now, we at label.co.uk have been offering more than relief embossing and blind embossing. We expanded our range of high-quality finishes to include micro embossing. Micro embossing is an innovative technique that creates eye-catching and delicate effects. Like relief embossing, this practice works with the help of specially manufactured embossing tools. Its intricate nature is both fascinating and complex. We therefore consulted an expert on the subject to gain a more detailed insight into the possibilities of implementation.

Interview with an Expert

The embossing tools we use for micro embossing are manufactured by Hinderer + Mühlich. H+M is a global company and leading manufacturer of die cutting tools.

Sascha Dremel is a Business Development Manager at Hinderer + Mühlich. Among other things, he is an expert in the field of micro embossing and took the time to answer some of our questions.

What material are your embossing tools made of?

“Our MicroEmbossing tools are made of high-quality brass. This material is particularly suitable for creating even the finest structures with high precision.”

What effect do different embossing materials have on the finished, embossed product?

“I have summarised the most important points to explain why brass is the material of choice:

Brass has excellent heat-conducting properties. As a result, it ensures lower energy consumption than other embossing materials. This type of efficiency not only saves you time, but also costs and energy.

Brass has excellent heat-conducting properties. As a result, it ensures lower energy consumption than other embossing materials. This type of efficiency not only saves you time, but also costs and energy.

Brass embossers last longer and wear out less quickly. This counteracts excessive waste and contributes to both cost efficiency as well as a responsible approach to the environment.

Brass embossers last longer and wear out less quickly. This counteracts excessive waste and contributes to both cost efficiency as well as a responsible approach to the environment.

Brass is particularly resistant to corrosion and can therefore withstand long periods of storage. This also ensures that these embossing tools can be used over a long period of time.

Brass is particularly resistant to corrosion and can therefore withstand long periods of storage. This also ensures that these embossing tools can be used over a long period of time.

Thanks to the special surface structure of the brass, the tools achieve extremely high-quality and, above all, precise results. From minute structures to razor-sharp reliefs, brass embossers are real all-rounders.”

Thanks to the special surface structure of the brass, the tools achieve extremely high-quality and, above all, precise results. From minute structures to razor-sharp reliefs, brass embossers are real all-rounders.”

Which label materials are your embossing tools suitable for?

“H+M embossing tools can be used with all paper materials. Coated materials are best suited for MicroEmbossing. With other materials, it depends on the combination of the material and the desired pattern. Depending on these factors, the motif may not be as visible as you’d wish. We are happy to provide an initial assessment of feasibility in advance.”

Can your embossers be combined with all hot foils?

“Basically, yes – our tools are compatible with all common hot foils. The important thing is to correctly match the temperature, pressure and time to the respective foil thickness and label material.”

Does micro embossing also work without foil? In other words, can the label material per se be deformed?

“With MicroEmbossing, the label material is not deformed; the effect is created by the play of light and shadow on the foil. The effects can therefore not be achieved with blind embossing.”

How delicate can the elements that are embossed with your tools be? (minimum line thickness)

“The minimum line thickness is 0.08 mm. In the negative area, you need 0.3 mm so that these areas do not smear.”

Do you have any general application recommendations for customers who would like to enhance their labels with micro embossing?

“It’s important that a suitable material is used; otherwise, there are very few limits to your imagination.”

Take a Look for Yourself

Interested?

Have we sparked your interest? Request samples today! If you would like additional personal advice, please feel free to contact us. We will help you find the ideal label solution for you.

Design with the professionals

Perhaps your curiosity is now piqued and you would also like to have labels with micro embossing elements, but somehow you lack the final vision? Then you’ve come to the right place! label.co.uk features a team of creative graphic designers. Our experts for inspiration will be happy to help you design an innovative, unique and stunning label with (or of course without) micro embossing.

Katharina Crusius

Marketing

Sascha Dremel

Business Development Manager