Updated: 05 November 2024

Printing with Thermal Printers: We Tested Them so You Don't Have to

Whether best-before date, weight information or ingredient list, subsequently printing on their labels is an important issue for many of our customers.

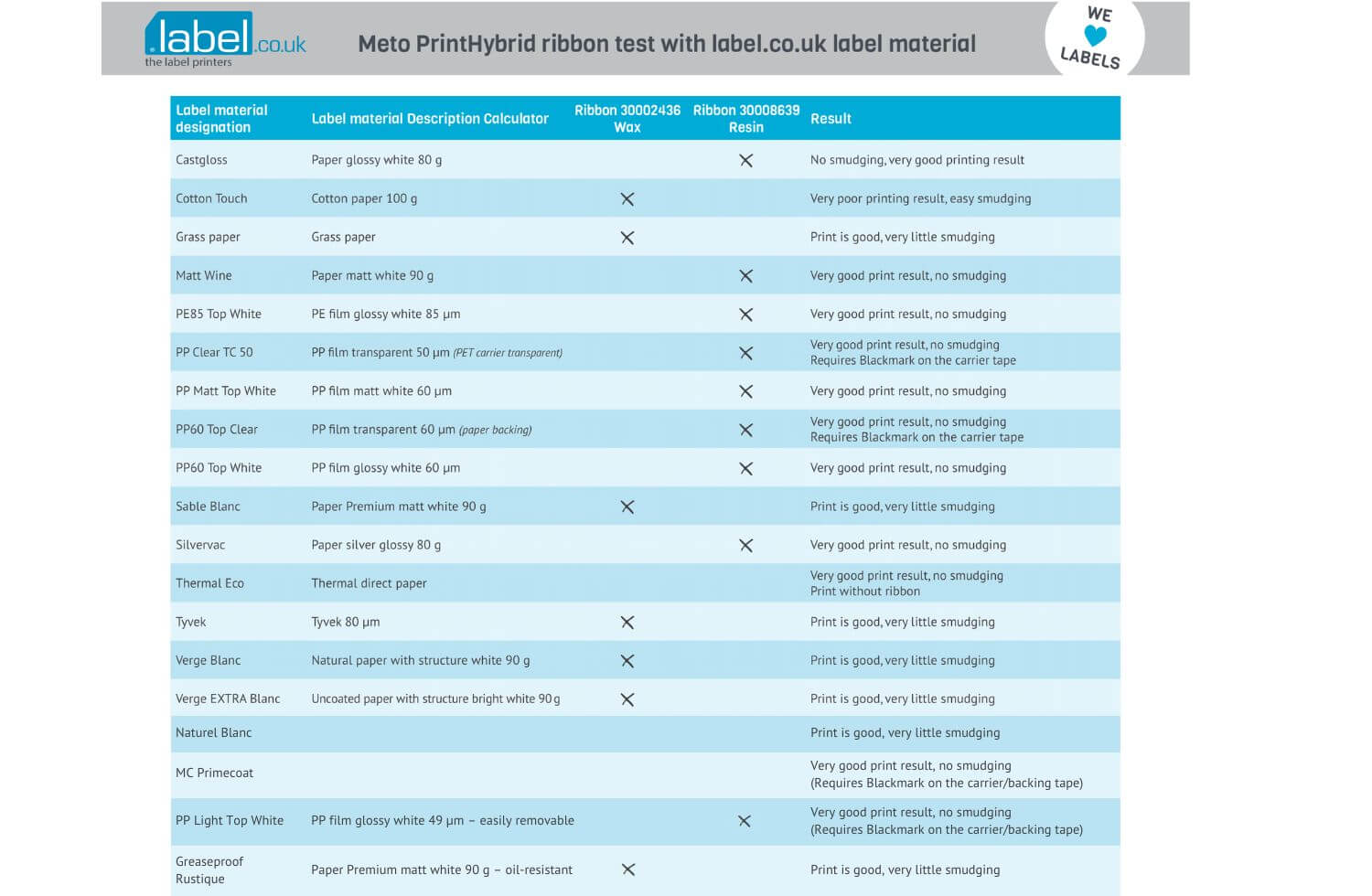

In order to be able to give our customers even better material recommendations for their respective applications, we carried out a field test in cooperation with Meto testing thermal transfer printing with their PrintHybrid thermal printers. Meto’s PrintHybrid thermal printers can print labels in both direct thermal and thermal transfer. Meto_PrintHybrid

We have carried out this field test for all our standard materials, which can be selected in our calculator. Both a wax and a resin ribbon were used. The direct thermal paper was imprinted using the direct thermal method without a ribbon.

Difference Wax Ribbon and Resin Ribbon

The two kinds of ribbons are mostly differentiated by their components and the resulting traits. Wax ribbons consist of carbon and wax, while resin ones are made up of carbon and resin. Because the printing done with resin ribbons is the most durable, they are also the costliest. However, that also makes them the best choice for harsh environmental conditions, such as moisture and UV light, and use in pharmaceutical contexts.

In contrast, wax ribbons are very cost-effective but offer less durability. Their printing is less resistant to external influences like scratches, smudges, and chemicals. Therefore, labels printed with wax ribbons are suited for short-term rather than long-term use (e.g. frequently changed price labels or inventory documentation).

How to Use the Different Ribbons?

Which ribbon to use depends mainly on the material to be imprinted: For films, we recommend a resin ribbon, as wax would not be smudge-proof. With (open-pored) papers we recommend a wax ribbon, as resin does not hold well on porous surfaces.

Print speed and temperature also influence the field test result: if the print temperature is too hot and the speed too low, there is a risk that the print head will burn through the backing/carrier – especially with foils. However, print speed and temperature can also influence the colour: If you want to achieve a black that is not quite as rich, you can combine a low temperature with a fast printing speed and get a grey tone.

The Results Are in:

The following table summarises which ribbon was used with which material and how the field test result turned out (click to zoom in & download)

Further Information:

If you would like further information on the materials you can choose at label.co.uk, please head over to this page.

Katharina Crusius

Marketing